Plinth

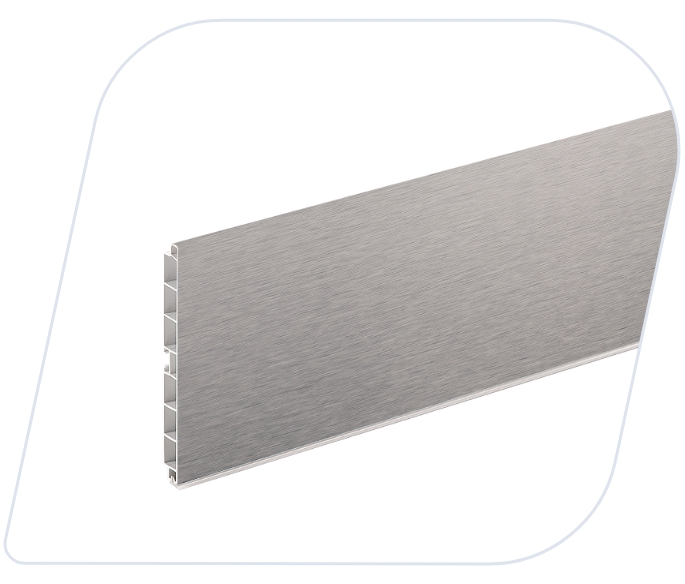

The Unionplast plinth collection is made of PVC using extrusion technology. The collection is versatile and offers the possibility of multiple finishes capable of meeting any requirement.

Special request on demand

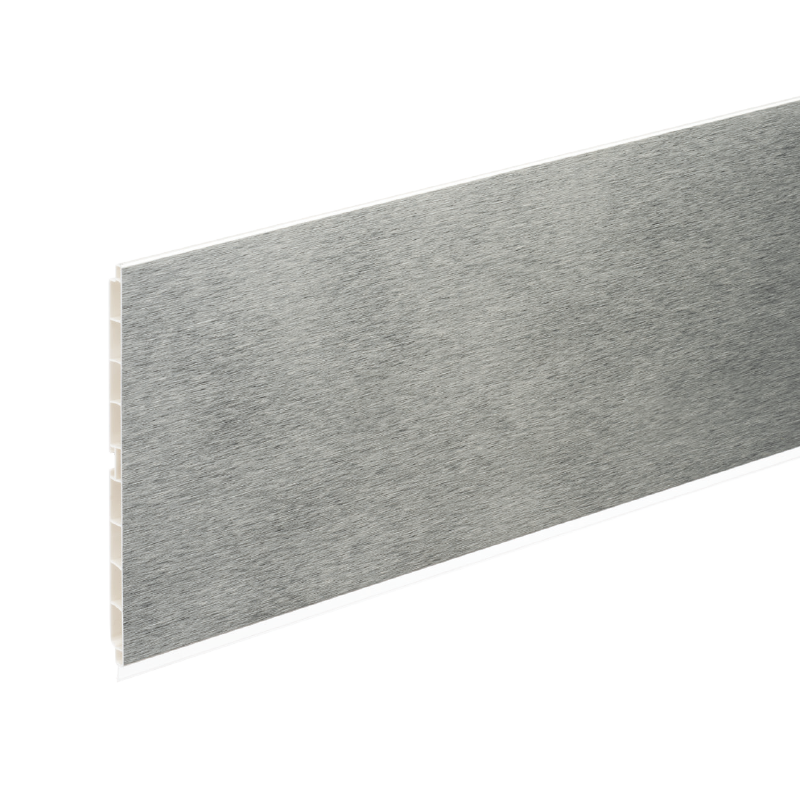

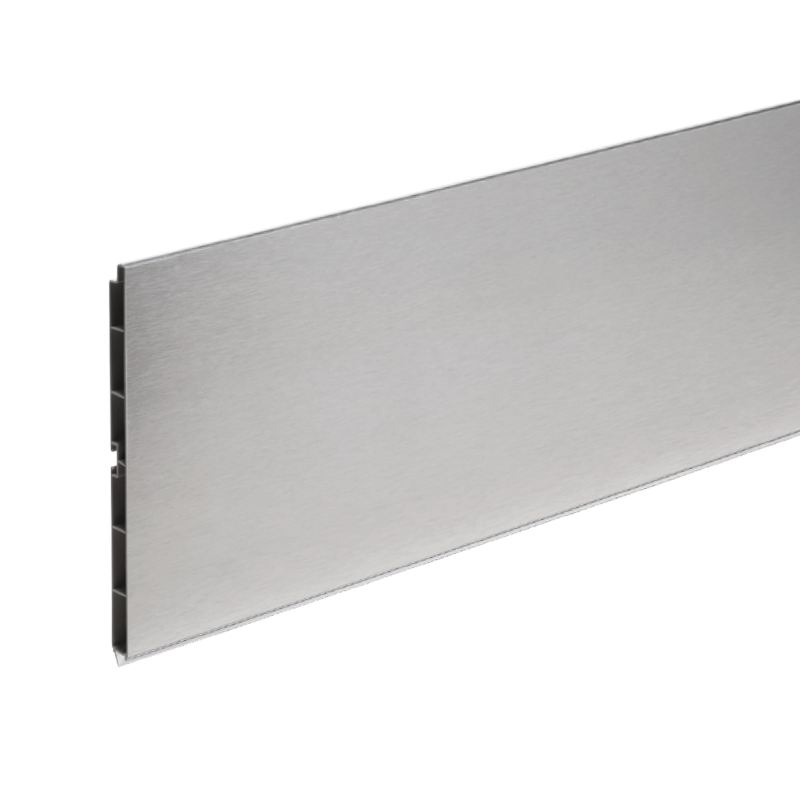

Plinth 310

The 310 plinth is produced through extrusion and represents the first generation of plinths developed by Unionplast. The gasket, applied after the extrusion process, can be easily removed and reapplied. This feature makes it particularly suitable for applications requiring painting, offering practicality without compromising the product’s quality.

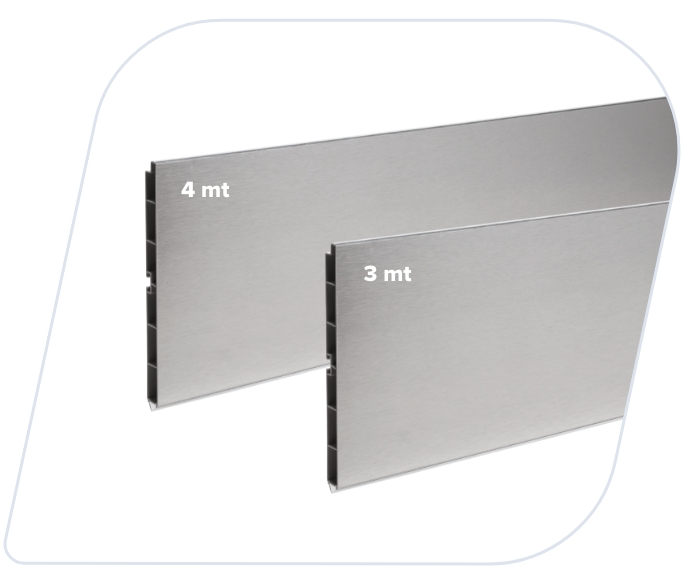

Customized cutting

Unionplast standard bars measure 400 cm; however, respecting minimum quantities, you can request custom-cut sizes.

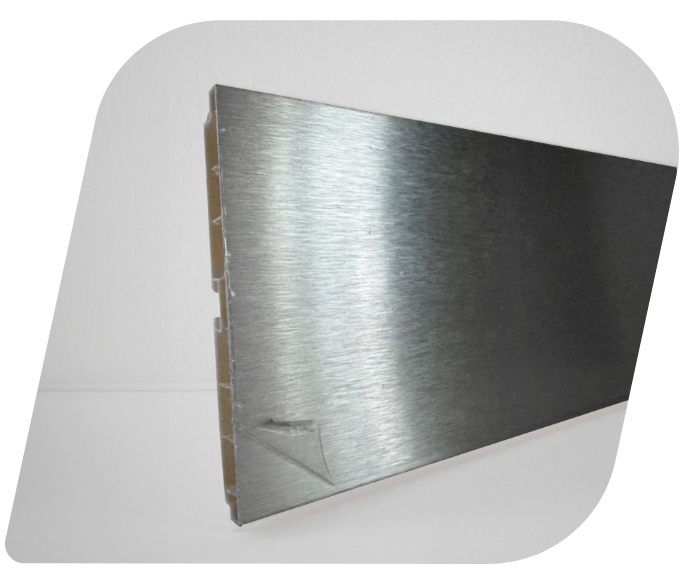

Anti-scratch protective film

On aluminium finishing, Unionplast provides plinth bars equipped with a special anti-scratch protective film; this can also be requested for paper finising.

Special packaging

Standard plinths are supplied neutral, without the Unionplast logo on the product or packaging. Upon request, both can be customized with the customer’s logo or name.

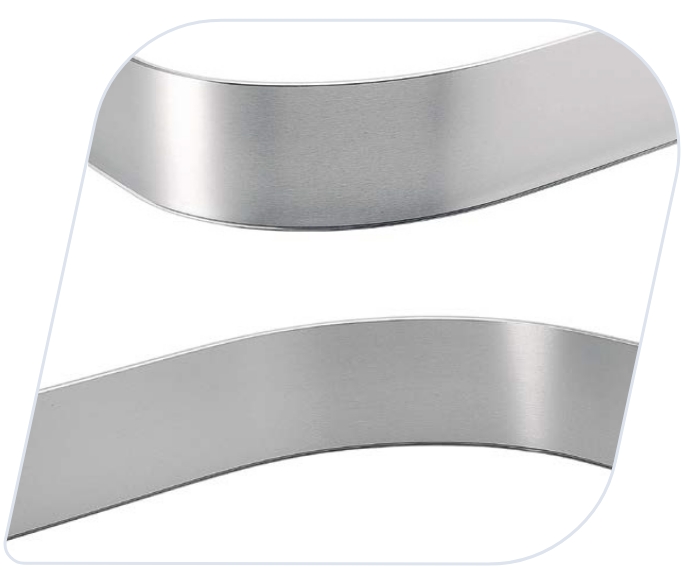

Curved plinth

When the kitchen requires it, the plinth can be supplied with a curvature. Curved plinths are manufactured following requested radius specifications, in various heights, lengths, and finishes.

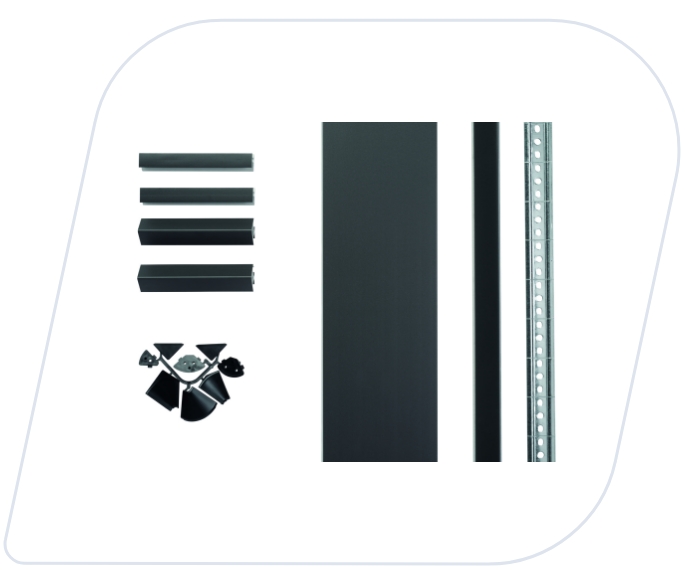

390 Plinths kit

Custom kits can be assembled on request with plinths, backsplashes, joints, and accessories, tailored in size and finish. Supplied in a single box or shrink-wrapped packaging.